TYPICAL CUSTOMER REQUIREMENTS

- Monitoring product quality through the sight glass

- Regulation of production process in time

- Material flow monitoring to prevent blockages

- Clear, detailed view with Full HD resolution even in difficult light

- Simultaneous image access from several workstations

- Elimination of time-intensive inspection rounds

- Fail-safe systems due to redundant solutions (e.g. with pre-installed encoders, switches, power supplies)

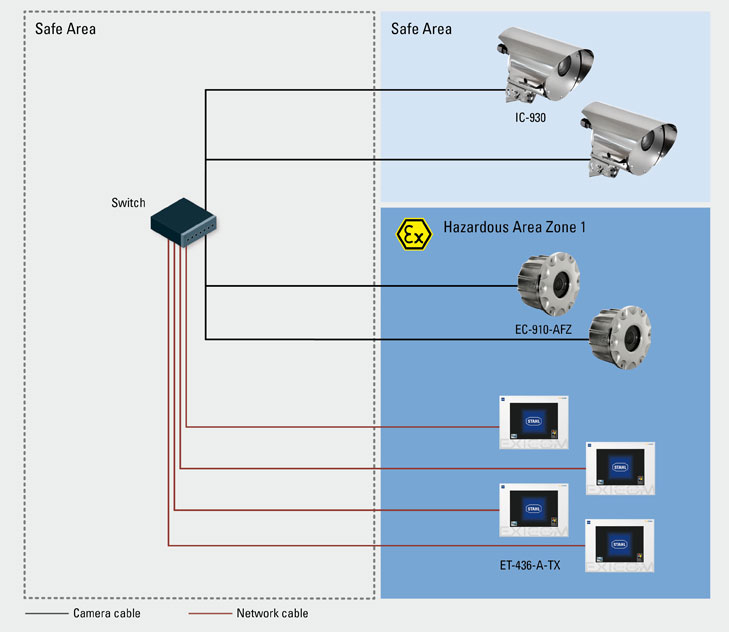

EXAMPLE OF A SYSTEM SOLUTION

CCTV REQUIREMENTS:

Our customer wanted to be able to react swiftly to any foaming in batch reactors with the aid of side glass inspection, and to save all video data in a server matrix for documentation and tracking purposes. The darker, safe outdoor areas should also be monitored and recorded.

CCTV SYSTEM SOLUTION:

For the optimum detection of any foaming in Zone 1 our customer chose the full HD AFZ camera. Its brilliant image quality and light sensitivity guarantee excellent images of the production medium inside the batch reactor. The camera shows any changes to the production medium or blockages in the flow system. The light-sensitive IC-930 with low-light technology is used to monitor the safe areas. This camera provides clear images even in darkness. HMIs as Panel PCs at various locations in Zone 1 are used for visualisation, enabling the user to immediately intervene in the process when necessary.

All video data is transferred via a switch to the control room and a redundantly designed server matrix for later tracking and documentation. With this video recording, the CCTV system automatically contributes to the complete documentation of the production processes.

OUR PRODUCTS AND SERVICES

- Excellent image quality for remote evaluation of product quality during operations

- Test assembly on site, as well as simple, cost-saving installation

- Compact size for tight spaces

- Lightweight

- Excellent value for money

- Vibration and shock-resistant solutions for rough environments

- Fast planning of the overall system including trial version on-site

- Fast payback due to elimination of inspection rounds

- Full documentation

YOUR QUESTIONS ARE OUR PRIORITY

Please get in touch with our contact person