Have you heard of the NEXdGEN project? The name NEXdGEN comes from "Normative adaptation to the static and dynamic stress on enclosures with 'flameproof enclosure' (Ex d) type of protection". Together with the Physikalisch-Technische Bundesanstalt (the National Metrology Institute of Germany), we are leading this project with the aim of optimising standards requirements within the context of the Ex d type of protection. This collaboration is being performed within the framework of the WIPANO (Wissens- und Technologietransfer durch Patente und Normen – "Knowledge and technology transfer via patents and standards") support scheme. It is intended to pass on the latest discoveries in standards research, making this available to the public and the economy.

Joint project with the PTB

The corresponding standard (IEC 60079-1) must be permanently revised to ensure the best possible testing of the enclosure properties for the Ex d type of protection in accordance with the state of the art. The NEXdGEN project will determine the influencing factors and their effect on material stress. The PTB is in charge of the project and is responsible for the design, execution and evaluation of the tests. We are providing test specimens and performing the same measurements at the R. STAHL laboratory. The tests will be evaluated jointly and the results will be incorporated in the next version of the standard.

"Flameproof enclosure" (Ex d) type of protection

Tests in accordance with the IEC 60079-1 Ex d standard

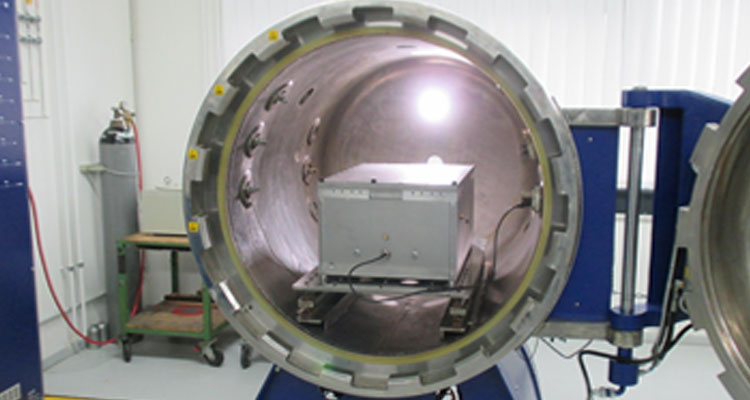

One of the tests carried out as part of the NEXdGEN project is the determination of the reference pressure. Here, the maximum explosion pressure inside the Ex d enclosure is determined. For safety reasons, tests of this kind must be carried out in our Ex d test facility in our laboratory.

During the test, a specified explosive air-gas mixture is introduced into the test enclosure, ignited and the resulting pressure inside the enclosure is determined. Apart from an audible "click", which may vary in volume, nothing is heard here during the test. The determined maximum explosion pressure (reference pressure) serves as the basis for dimensioning the enclosure.

As part of the type test for certification tests, a static pressure test must be carried out on the enclosures to be certified. The result of this test then determines whether a static pressure test must be performed on the finished housings later as an individual routine test, as a batch test, or not at all. The test pressure for the routine test and for the batch test must be 1.5 times the reference pressure.

Test for non-transmission of an internal ignition

With regard to the Ex d type of protection, in addition to the test for the reference pressure, the test for non-transmission of an internal ignition is probably one of the most interesting tests in the laboratory. Here it is demonstrated that all joints in the enclosure safely prevent the propagation of the explosion to the outside. For this purpose, the same explosive gas mixture is introduced into the Ex d enclosure and into the direct vicinity of the enclosure – i.e. into the test boiler – during the test. If the gas mixture inside the test enclosure is ignited and the surrounding gas mixture is not ignited, the enclosure is flameproof.

In order to cause ignition transmission, we deliberately expand a joint in an Ex d enclosure. The joint width of the plane joint between the enclosure and cover is chosen so that it is large enough to ensure that the internal explosion is propagated to the outside. This illustrates the effect on a potentially explosive environment outside the enclosure. This explosion generates a loud bang.

Images of the course of an explosion from the inside of the Ex d enclosure into the interior of the test facility, taken using a high-speed camera that takes 1000 images per second:

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-startseite-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-ueber-den-blog-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-autoren-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-newsletter-expert-mail-279x205.jpg)

Write new comment