SETTING NEW STANDARDS FOR DIGITALISATION IN THE PROCESS INDUSTRY

Digitalisation has become synonymous with progress and development in the process industry. Its overarching aim is to establish intelligent human-machine and machine-machine networking for efficient process automation. Process monitoring and diagnostic data evaluation all the way out into the field play a key role here. This is even more true in hazardous areas.

New concepts such as NAMUR Open Architecture (NOA) and the Open Process Automation Standard (O-PAS™) require a powerful, flexible infrastructure. A network standard that offers high bandwidths and fast transfer rates in the field – and all that with simple installation.

The solution? Ethernet Advanced Physical Layer, or short Ethernet-APL – the international standard for Ethernet in the field.

ETHERNET-APL: DATA TRANSMISSION TECHNOLOGY WITHOUT LIMITS

Ethernet Advanced Physical Layer data transmission technology is the new standard for 2-wire Ethernet. Ethernet-APL is specifically optimised for use in systems within the process industry and enables cutting-edge, digital structures to be established. Continuous IP communication from the field level to the control system – and even beyond – is possible, as is horizontal and vertical networking across entire systems.

Ethernet-APL is based on the 10BASE-T1L specification from IEEE Std 802.3cg-2019 and specifically enhances this for use in the process industry. There's more – this sophisticated data transmission technology supports the "i" intrinsically safe type of protection in hazardous areas in Zones 0, 1 and 2 (in accordance with IEC 60079-11 and IEC 60079-25) as well as Class I Div. 1 and Div. 2 (NEC500). In contrast to Power over Data Lines (PoDL) from the Single Pair Ethernet (SPE) specification, Ethernet APL uses a different supply concept. Instead of industrial plug connectors, installation takes place primarily via terminal connections typical in the process industry.

How Ethernet-APL works in process automation

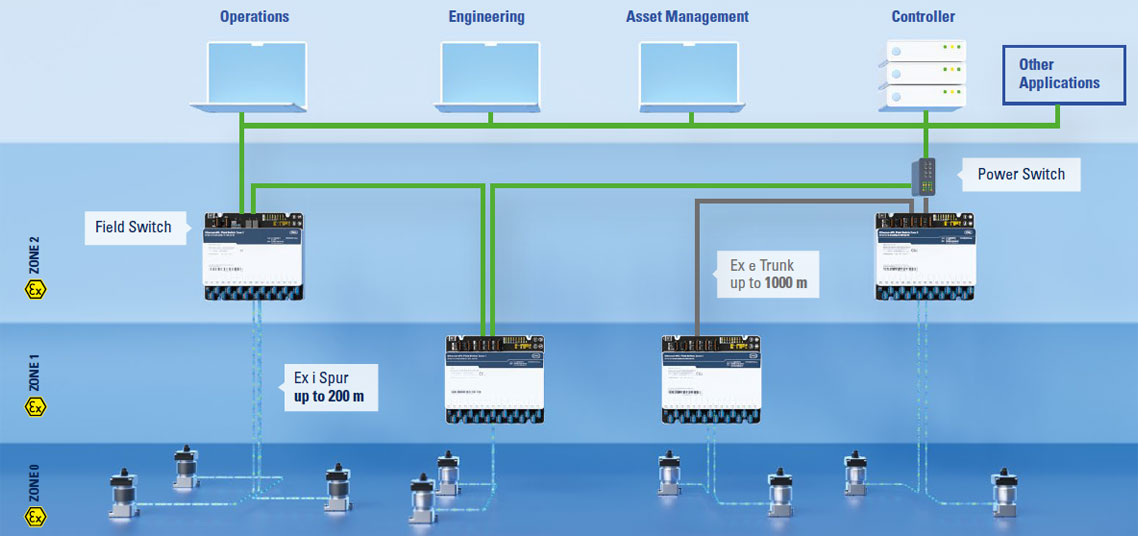

Ethernet-APL supports a number of installation concepts. This includes the star topology, which has proven successful in Ethernet applications. It is particularly easy to plan and supports redundant networks (rings) with typically up to 250 field devices. For this purpose, Ethernet-APL field switches with an external power supply are directly operated in Zone 1 or Zone 2 using industrial 4-wire Ethernet 100BASE-TX or 100BASE-FX. These switches then provide the connected Ethernet-APL field devices with intrinsically safe power.

The trunk-and-spur topology can be used as an alternative. With this type of topology, a power switch feeds power into the lower-level network and is responsible for conversion from 4-wire Ethernet to 2-wire Ethernet. The field switches (powered by the trunk) and the intrinsically safe Ethernet-APL field devices are then connected to this trunk, which is up to 1000 metres long.

One thing that both options have in common is the new intrinsic safety concept for the Ethernet-APL field devices: "2-Wire Intrinsically Safe Ethernet" (2-WISE) based on the tried-and-tested FISCO (Fieldbus Intrinsically Safe Concept). Even the type A cables typical of fieldbus applications can continue to be used. R. STAHL contributed to this new Technical Specification (IEC TS 60079-47) at the IEC level.

Tests and certifications ensure that devices from different manufacturers are interoperable within the same network.

ETHERNET-APL: THE FUTURE OF PROCESS AUTOMATION

The development and market readiness of Ethernet-APL were driven by the collaborative work of 12 manufacturers and the leading technological associations FieldComm Group (FCG), ODVA, OPC Foundation and PROFIBUS PROFINET International (PI). The APL working group started its work in 2018 and successfully completed it in August 2022 – Ethernet-APL is ready for implementation in practice.

The technological associations are currently working with manufacturers on certification measures to ensure that the products are interoperable. Some end users are already in the process of trialling the new technology in their testing laboratories to check that it is suitable for practical use. Ethernet-APL is impressing with outstanding results.

The first Ethernet-APL field devices and infrastructure products will be available on the market by the end of 2023, while many more have been announced for 2024. On the part of NAMUR, an APL Task Force is actively working in close collaboration with the ZVEI and its member firms on promoting and using the technology – when will you get on board with Ethernet-APL?