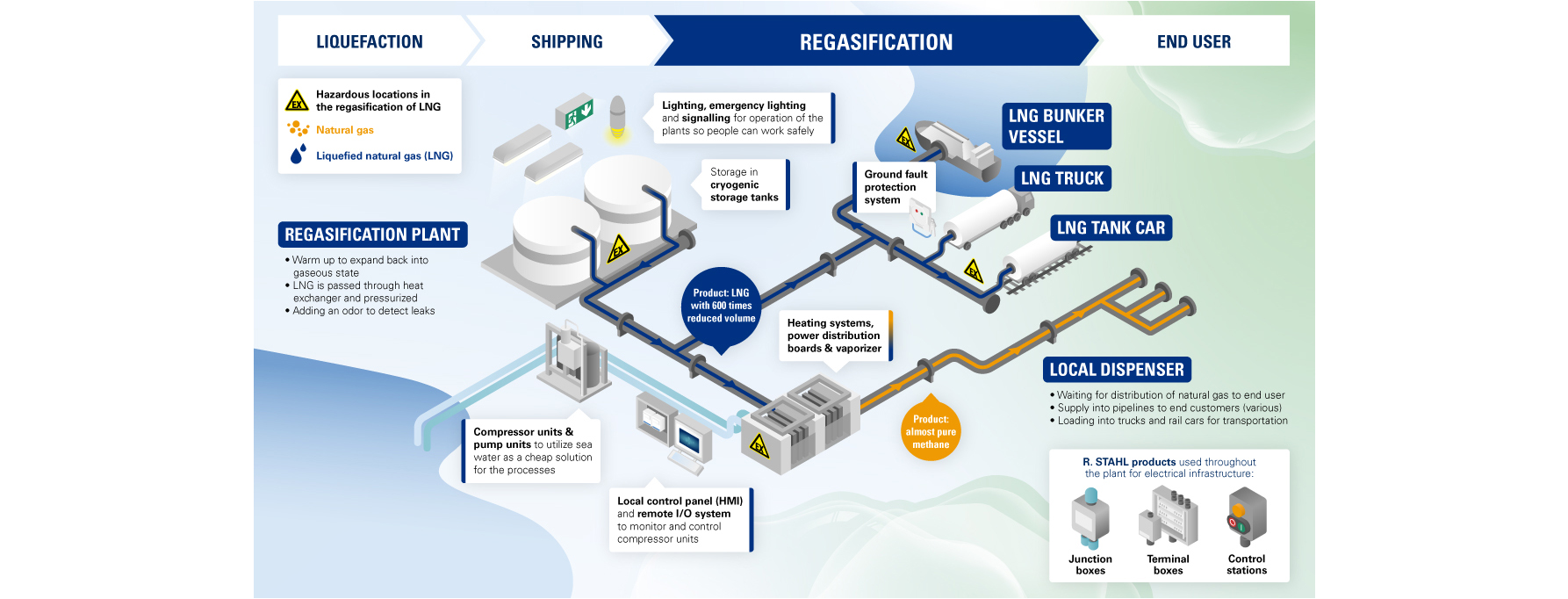

Minimizing explosion hazards in LNG regasification plants

Before liquefied natural gas (LNG) can be used in process plants or power plants, or fed into the gas pipeline, it must be turned back into a gaseous state. For the regasification process, the heat required for vaporisation is supplied via heat exchangers to the natural gas, which has been cooled to -162 °C. Seawater is generally used as a heat exchanger on onshore terminals and on FSRUs (floating storage and regasification units). At decentralised, smaller storage tanks, however, ambient air vaporisers are usually used for LNG regasification. If the re-gasified natural gas is to be fed into a gas transmission grid or distribution grid, it must first reach a certain pressure. Compressors of various construction types are used for this purpose.

In an LNG terminal, on board an FSRU or at a satellite LNG station, the hazardous zones cover large areas of the plant; as a result, explosion protection solutions from R. STAHL are not only used during the actual processing stage, but throughout the entire infrastructure. The ignition hazards during regasification and supply of natural gas to the grid can be mitigated with suitable construction and electrical explosion protection. This means an explosive mixture of natural gas and air should ideally never occur. And if it does, it must not be ignited either by sparks or hot surfaces. This is ensured by using suitable explosion protection solutions, such as devices, protective systems and components that are certified for use with gases in explosion group IIA and temperature class 1. Depending on the application range, they must be classified for Zone 0, Zone 1 or Zone 2 and appropriately certified.

Moreover, many systems are in close proximity to the coast or are even operated offshore. Seawater-resistant enclosures with high-quality seals safeguard the explosion-protected components and systems here. For FSRUs, vibration resistance and a high level of EMC protection are also required. R. STAHL provides a comprehensive explosion-protected portfolio of products for all processes related to regasification. Some products have ship approval and can even be installed on deck.

Protection needs a strong partner

We are a leading supplier of explosion protection equipment with a globally certified portfolio of products and services that keep everyone in the LNG value chain safe. What is more, our decades of experience in the field allows us to customise our solutions.