Protecting lives and assets in LNG liquefaction plants

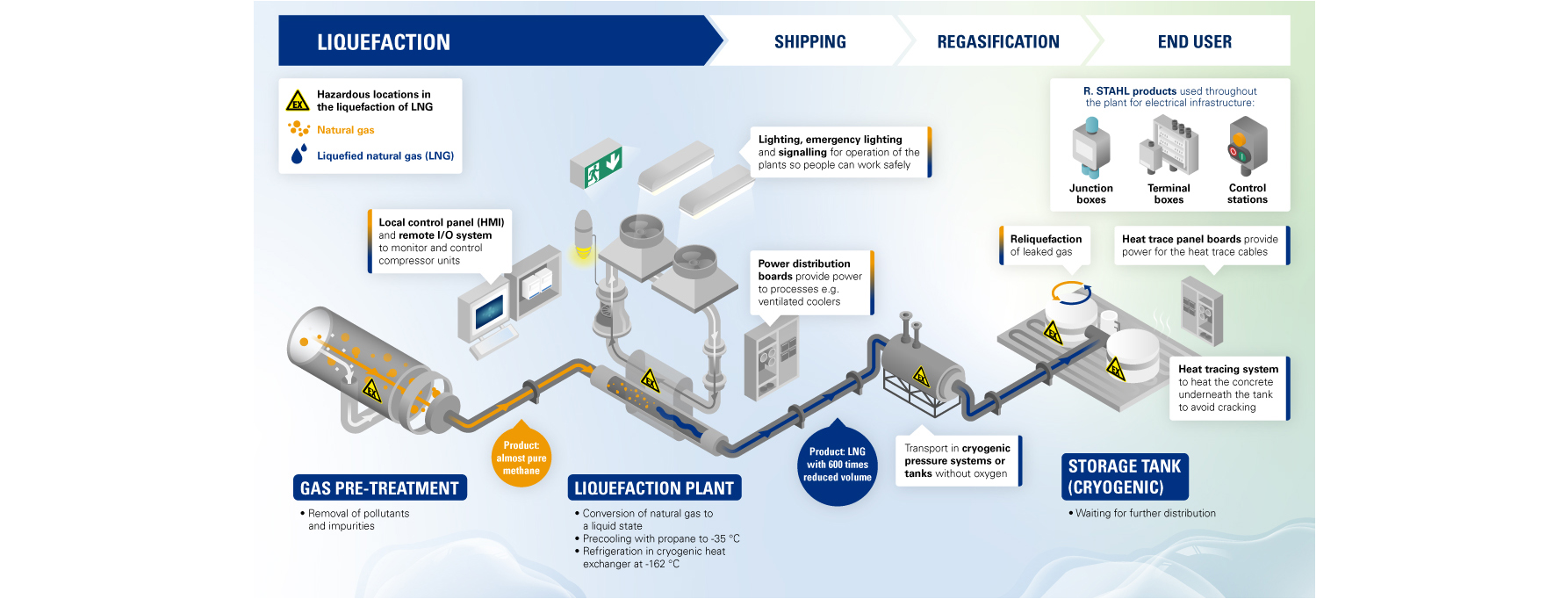

LNG is produced by cryogenically cooling natural gas to a temperature below -162 °C in a gas liquefaction plant (LNG train). Before this can occur, however, detrimental or toxic components in the raw natural gas need to be separated out via a process of absorption, washing out or pre-cooling to -35 °C. The actual process of liquefaction of almost pure methane consists of a sequence of compression, cooling (heat extraction) and pressure relief stages, which is repeated until the natural gas has reached liquid state.

The requirements regarding explosion protection are extremely strict. Natural gas and LNG are extremely flammable; according to ATEX and IECEx, they belong to explosion group IIA. There is an explosion hazard not only during the actual liquefaction process, but through out the entire process, including purification and transport to individual plants or plant parts. As a result, consistent explosion protection measures must be implemented throughout.

Liquefaction plants are frequently installed at port terminals, where the LNG can be loaded onto transport ships. However, liquefaction also commonly takes place offshore at the natural gas extraction site. Floating LNG (FLNG) plants are used for this purpose.

A range of pumps, compressors and/or turbines are used in all these process steps. They convey natural gas to the individual cleaning systems and the LNG train itself, compress it and relieve the pressure. In addition, the heat exchangers must be supplied with coolant, which may also be highly flammable. Pumps are required for this task, as well. To guarantee explosion protection, a range of types of protection are suitable, such as flameproof enclosure (Ex d), pressurised enclosure (Ex p), increased safety (Ex e) or encapsulation (Ex m) versions. Several degrees of protection can also be combined. Using enclosure technology with a modular design, actuators and power distribution boards can be configured in different sizes, including configurations that allow very high outputs with many current outlets in hazardous areas.

Protection needs a strong partner

We are a leading supplier of explosion protection equipment with a globally certified portfolio of products and services that keep everyone in the LNG value chain safe. What is more, our decades of experience in the field allows us to customise our solutions.