Safe transportation of sulphur dioxide

Nigeria's industry has once again become even more wealthy with another petrochemical plant. Amongst other things, this major project required a process gas compressor for transporting contaminated, aggressive sulphur dioxide. This was developed by one of the global market leaders for turbo compressors for small volume flows and Zone 0 machines. One important requirement was to design a compressor for Ex-Zone 2. The result was a close cooperation with the experts in explosion protection, R. STAHL. During planning and implementation, the two companies were confronted with four challenges:

- The customer's request to supply electrical components in Ex d.

- Requirement for a compact switch cabinet solution.

- Wear, due to how the sulphur dioxide is transported.

- Consideration of climatic conditions.

Power supply in Ex d

The requirement to make all electrical components suitable for Ex d would mean an extremely expensive, difficult and large-scale solution. The technical specifications were analysed in detail in order to present the customer with a tailor-made solution which would save them money and space. This revealed that a focus on Ex d with regards to the power supply was sufficient. The optimum solution for the customer was therefore the combination of Ex d, Ex e and Ex i types of protection. This meant that the supply was centralized in an Ex d enclosure and linked to an Ex e cabinet with the rest of the devices.

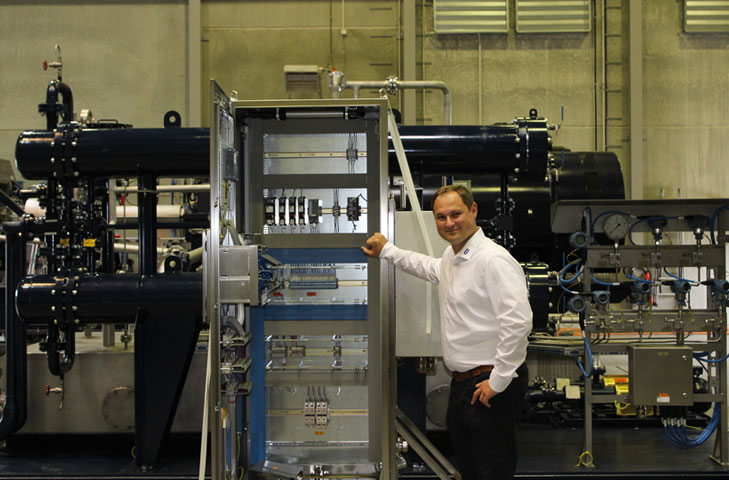

Compact cabinet solution

This effortlessly solved the challenge of accommodating the majority of the electrical components in a bundled and compact manner. The display panel for the Ex i type of protection was integrated in an Ex e cabinet. This contains control panels as well as displays for monitoring and for error messages. The clear and compact structure made handling significantly easier for the customer.

Cleaning without interrupting the production process

Despite the compressor's optimized power supply, gradual wear had to be taken into consideration. When the highly contaminated, aggressive sulphur dioxide is transported, over the course of time its particles are deposited on important sensors, for example. So the sensors affected have been integrated in the machine so that it is possible to clean them without interrupting the production process. The existing standard machine design with cleaning openings was modified and extended to include the flow measurement sensor.

In addition, the particles also settle on the impeller, which can result in imbalance. This, in turn, causes vibrations which can be transmitted to the upstream shaft, and from there to the upstream gearbox. This issue was solved by placing an additional bearing unit between the gearbox and the compressor. This is used to protect the upstream gearbox from impeller vibrations and reduces the risk of irreparable damage to the gearbox.

Stainless steel solutions defy the climatic environmental conditions

However, the quality of the two global market leaders could be seen not only in the development of the optimum and individual customer solution, but also in the selection of the building materials. This played an important part with regards to the machine design and the electrical components, as well as on site because of the ambient conditions. Proximity to the coast, occasional tropical storms and general climatic conditions have an influence on the material. This is why highly resistant stainless steel was used for the impeller, its enclosure and the cabinets.

Conclusion

Expertise, flexibility and advice at any time are just some of the key factors involved in the repeated successful collaboration. Whether you are looking for a standard or customized solution, if you are presented with a large number of challenges, together we will find the right one for you.