Stop sparks from jump over

Where combustible substances, oxygen and a source of ignition meet, there is a risk that they will cause an explosion. The intrinsic safety type of protection is designed to prevent this exact scenario by eliminating one element of this explosive trio. In an intrinsically safe circuit, the amount of energy is reduced to a non-ignitable extent, which therefore eliminates the source of ignition in the form of sparks and thermal effects. With this, an ignition can be prevented for normal operation and, depending on protection level, even under fault conditions.

Over 50 years ago, the first intrinsically safe field devices and associated safety barriers were used for the first time. Since then, the variety and versatility of applications has continued to grow. Now, the intrinsic safety type of protection (Ex i) is widely used – explosion protection is unimaginable without it. This type of protection covers a wide range of applications and is currently used in systems ranging from simple point-to-point wiring to digital automation for IIoT. Ex i-protected solutions enable direct process data capture in hazardous areas, reduce installation work and can be checked and maintained during ongoing operation.

For years, intrinsically safe fieldbus versions have been primarily used to network remote I/O devices, operating terminals and analysis equipment. In addition, Ex i-protected fieldbus installations with PROFIBUS PA or Foundation Fieldbus H1 have proven to be useful for digital communication up to field devices. These developments didn't stop at wireless technology, either – in this sector, intrinsic safety allows more flexible use of antennae. Currently, the trend is heading towards intrinsically safe solutions for Industrial Ethernet. To drive the development of internationally accepted intrinsically safe Ethernet concepts, R. STAHL also actively participates in the Advanced Physical Layer (APL) project and the Intrinsically Safe Ethernet Working Group. Here, you can read more about intrinsic safety, seminars and services in this sector, and R. STAHL's Ex i interface solutions.

THE ADVANTAGE OF INTRINSIC SAFETY

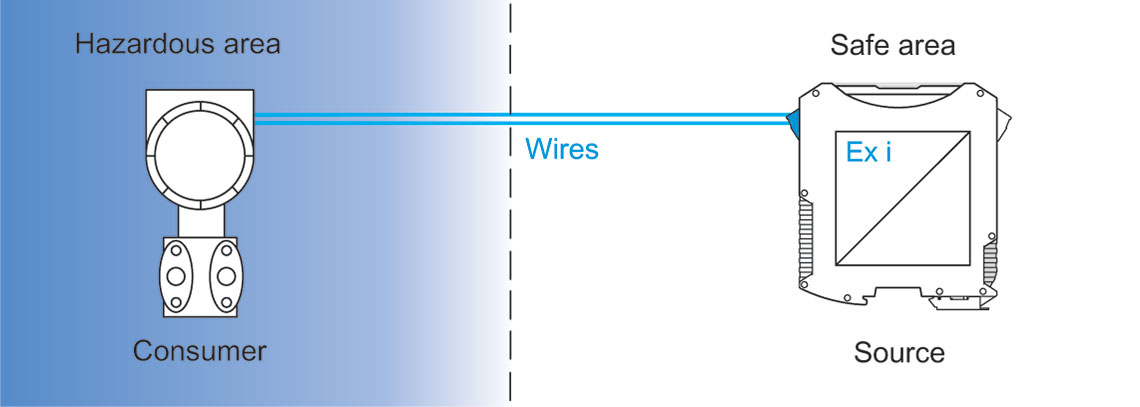

Compared to other common types of protection, such as "Ex d" flameproof enclosures and "Ex p" pressurized enclosures, the intrinsic safety type of protection does not require any special enclosures that prevent an explosion that occurs inside the enclosure from being transmitted to the outside atmosphere. In this sense, this type of protection always comprises a combination of current/voltage sources, cables and consumers, which are typically used in hazardous areas. This achieves very high levels of safety, allowing corresponding designs to be implemented even in extremely hazardous areas in Zone 0.

Ex i-protected devices are extremely practical in terms of their handling during ongoing operation. Extensions and repairs can be performed on live equipment in hazardous areas (hot work) and devices can be added or separated without having to shut down the system or parts of the system entirely (hot swap). This is especially beneficial when troubleshooting problems or swapping out devices.

Thanks to its simple handling, extremely high level of protection and versatile installation options, intrinsic safety is an essential type of protection for process automation and data communication in hazardous areas.

The ignition curve – the measure for intrinsically safe circuits

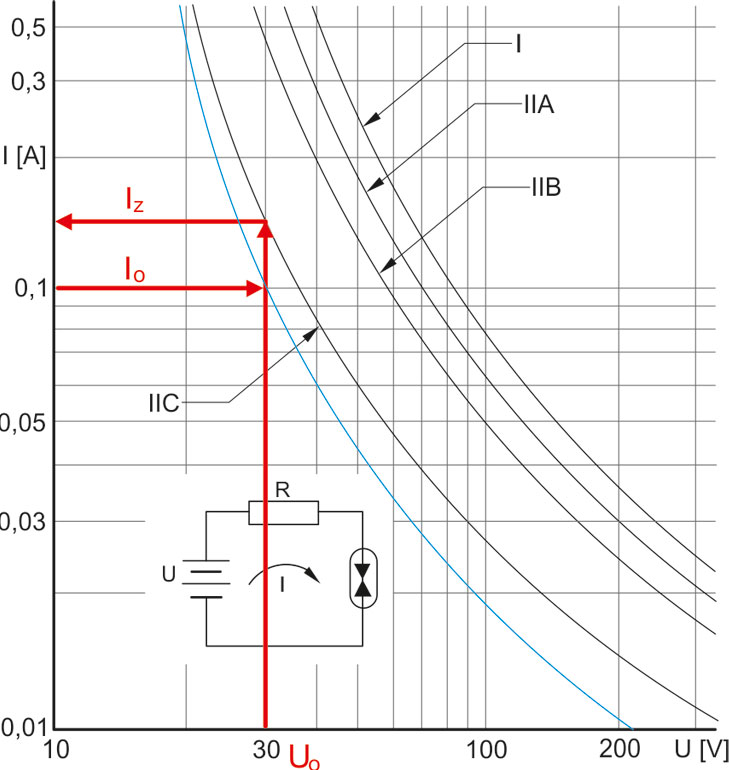

The maximum permissible values for ensuring intrinsic safety for voltage (U) and current (I) mentioned previously have been determined experimentally. They are determined using ignition curves – a curve exists for each explosion group. An electrical circuit is considered to be intrinsically safe if the pair of values made up of the voltage and current are underneath the ignition curve for the relevant explosive atmosphere. For use in Zone 1 or Zone 0, the permissible value is reduced by an additional safety factor of 1.5.

Example: In Zone 1 or 0, the permissible value must be reduced by the safety factor of 1.5. If equipment is running in Ex group IIC and in Zone 1, it can be supplied with a maximum of 102 mA.

For use in Zone 0, a device with intrinsically safe circuits must comply with these current and voltage values even if two errors occur. For circuits in Zone 1, this applies if one error occurs. For use in Zone 2, it is sufficient for these values to be complied with during normal operation.

Depending on the intended application range (Zone 0, 1 or 2), the letter a, b or c is added to the Ex i designation. The same addition also indicates the Equipment Protection Level (EPL) for equipment approved for use in Zone 0, 1 or 2. The EPL, which is written as Ga, Gb or Gc, is indicated in the EC Type Examination Certificate and on the device's type plate.

| Application area | EPL | Safety level | Without ignition | Intrinsic safety |

|---|---|---|---|---|

| Zone 2 | Gc | normal | during normal operation | ic |

| Zone 1 | Gb | high | during normal operation and with one fault | ib |

| Zone 0 | Ga | very high | during normal operation and with two faults | ia |

Verification of Intrinsic Safety

Before commissioning an intrinsically safe circuit, the intrinsic safety of the circuit must be demonstrated according to IEC EN 60079-14 in order to ensure that the source, cables and consumers meet the requirements of the standard when interconnected. As part of the explosion protection documentation, it must be verified that no sparks or hot surfaces result during operation. To obtain this verification, the values for the voltage, current and power of the circuit, as well as the capacitances and inductances of the energy storing devices are evaluated. If the output values for the voltage source, current and power (UO, IO, PO) do not exceed the input values of the connected consumer (UI, II, PI), and the connected capacitances and inductances of the consumers (CI, LI) and cables (CC, LC) do not exceed the limiting values (CO, LO), verification of intrinsic safety can be granted.

This verification must be documented. The values for the verification of intrinsic safety are taken from the operating instructions for the device in question. For the cable, either the values from the data sheet or worst case values from the standard can be used. The definitive values for the cable are determined using the length.

It is somewhat more difficult to obtain verification of intrinsic safety for consumers with simultaneously effective inductances LI and capacitances CI. Under these circumstances, users can either use values that have been certified for sources in this situation or they can halve the limiting values for CO and LO in accordance with the so called "50% rule". Particularly complex individual cases – such as electrical circuits that are supplied from multiple sources – require detailed calculations, which R. STAHL is happy to perform on request as a service.

Simple equipment is an exception – when implementing the intrinsic safety protective concept, certain equipment that is considered to be "simple" can be used without requiring an EU EC Type Examination Certificate. However, the use of this option demands caution, as it requires a thorough in-house assessment of these devices and equipment, such as switches, LEDs, thermocouples or Pt100 resistance thermometers according to IEC EN 60079-0 and 60079-14. Depending on the construction type, this involves evaluating factors such as heating behaviour, insulation to earth, IP protection, and more, as well as recording the results of these evaluations in writing. R. STAHL is happy to provide support to the sector during this process through standard-compliant evaluation and assessment of simple equipment.

Together for intrinsic safety

We take explosion protection seriously, and have done for almost 100 years. In doing so, we put our faith in active knowledge transfer in order to guarantee comprehensive safety for your staff and machines. This is why our lecturers, who are themselves long-term employees at R. STAHL and active in national and international standardisation bodies, designed a range of seminars and further training opportunities, particularly relating to intrinsic safety. This ensures that you remain at the forefront of explosion protection technology. As well as exciting theory, practical exercises ensure a deeper understanding. Learn more about our E-learnings!

ASK OUR EXPERTS

Please get in touch with us